Fuel and Oil for the MZ201 Engine

Fuel and lubricating oil are important for any engine. For a 2 stroke engine, where the engine is lubricated with a fuel/oil mixture fuel and oil are especially important. And, while fuel and oil are important for 2 stroke outboards, motorbikes and snowmobiles, they are critical for an ultralight.

Engine out failures in an ultralight most often result in emergency landings, so the importance of avoiding engine failures is obvious.

The most common engine out failures in two stroke engines are the result of detonation, excess deposits of carbon from unburned oil, seizures due to a lack of sufficient lubrication, or dirty contaminated fuel.

Fuel

Detonation or "ping" is caused by fuel that burns as an explosion rather than a relatively more controlled more gradual pressure increase over time. It is like hitting the piston with a hammer rather an a push. For the sake of simplicity, assuming ignition timing is set correctly, detonation is the result of fuel with insufficient octane rating, excess carbon deposits in the combustion chamber or incorrect air fuel ratio.

The correct air fuel ratio is usually just a matter of adjusting and/or jetting the carburetor correctly for air density and humidity.

So picking the right fuel becomes a bit of a research project. And, it must be remembered that adding oil to the fuel tends to reduce the octane rating.

Compact Radial Engines and now Fiate, manufacturer of the MZ201 recommend minimum 95 RON Octane gasoline. The engine is advertised to have a 9.6:1 Compression Ratio.

Gasoline sold at automobile service stations generally only share the AKI rating of the fuel. AKI is an average of RON and MON. Generally RON is higher than MON and AKI for the same fuel. e.g. 93 AKI "Supreme" gasoline at most service stations is equal to 98 RON, but it achieves with 10% ethanol. Most ethanol free gasoline at the service station pumps is 90 AKI, with an estimated 91 RON. Since 91 RON is too low and ethanol is not recommended for "aircraft", the only way to use "pump" fuel would be to blend it with Aviation Gasoline 100LL or an unleaded "racing-off road" gasoline.

100LL Aviation Gasoline has a MON of 100, with an estimated RON of more than 105 (As high as 110). A 50% blend of 90 AKI ethanol free pump gas and 100LL would result in a fuel that exceeds the minimum 95 RON requirement with an estimated RON of 98+. Sunoco 260GTX 98 AKI Racing Fuel has a RON of 103. A blend of 40% pump and 60% Sunoco GTX would provide an RON of 98 and it would be unleaded. (Too high an octane is not ideal as higher octane tends to burn more slowly, so there could be incomplete combustion and less power.)

Another option is Sunoco Optima 95 (what NASCAR Cup uses) which is unleaded and has an RON of 98. The advantage of the blends is that pump gas and Optima have a relatively high vapor pressure compared to 260GTX and 100LL. As of July 2022: Cost of the 100LL blend would be around $8 per gallon. Cost of the Sunoco blend would be around $12. Cost of the Optima or unblended 260GTX would be $18-20 per gallon including shipping costs.

It is possible that the MZ201 engine could run better with 103 RON vs 98, depending on ignition timing, so the Sunoco 260GTX might be ideal under certain circumstances. Detonation in an ultralight engine will likely not be detected by an audible "ping" like in an automobile. Signs of detonation will show up in the form of excessive CHT and depressed EGT with some loss of power. When octane is too high or the timing is not advanced enough, the engine will produce less power and will show a lower CHT. All of this complicated by the fact that flame speed is also affected by the fuel air ratio--too lean a mixture can produce the same effect as low octane. Slightly "rich" of peak is usually best.

Sunoco offers Optima 95 "pre-mixed" with a synthetic 2 stroke oil with a 40:1 ratio. The 2 stroke oil meets JASO FD and API TC Specs. Sunoco does not provide any other tech data on the oil. Since it is advertised as recommended for outboards, it might not be ideal for air cooled engines.

My best judgment will be to run Sunoco 260GTX and experiment with blending it with 90AKI ethanol free pump gas when ambient temps are lower. If 260GTX became unavailable, I would use 100LL blended with 90AKI. While 260GTX is more expensive, the convenience of buying in 5 gal pails, and the logistics of obtaining/transporting 100LL offset the cost.

Oil

The MZ201 Engine Manual specifies Castrol TTS as the desired oil, mixed at 50:1. Castrol TTS is no longer produced, so something else must be identified.

First let's look at the specs for Castrol TTS (as of 2016):

- Full synthetic 2-stroke motorcycle engine oil

- Creates a tough, heat-reactive layer of protection

- Designed for both oil injection and premix lubrication up to a fuel/oil ratio of 50:1

- Exceeds API TC, JASO FD, and ISO L EGD

API is the American Petroleum Institute, and TC is a very old standard met by almost every 2 cycle oil sold today.

JASO FD is a Japanese more stringent standard requiring lower smoke levels and more detergent.

ISO L EGD, a European standard is essentially the same as JASO FD, but requires a 3 hour test running a Honda engine to document piston cleanliness and detergent effectiveness.

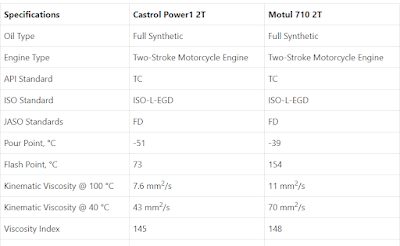

Castrol has introduced "replacements" for TTS, Castrol Power 1 2T. Amsoil Dominator is almost the same. Motul produces a similar product, Motul 710 2T.

Castrol Power 1 2T seems to be in very short supply in the US. Motul 710 is available from multiple sources. The Flash Point of 154C for the Motul is more desirable than the Power 1 2T and Amsoil as is the higher viscosity. The viscosity of Motul 710 is higher than Power 1, but lower at 100C than Castrol TTS. My opinion is that Motul 710 2T is equivalent and slightly better than the Castrol TTS.

Another "equivalent" oil would be from Motorex (Switzerland) Cross Power 2T. Flashpoint is 110C with Kinematic Viscosity at 40C of 60. This is in between Castrol and Motul 710.

Motorex Power Synt 2T is advertised as designed for “Supersport” motorcycle racing. Similar specs as Cross Power 2T.

Another "possible" oil would be Motul 800 Off Road 2T with Flashpoint of 252C, and Kinematic Viscosities of 120 and 15.

Flash Point C Viscosity@40C Viscosity@100C

Castrol TTS 89 43 22

Castrol Power 1 2T 73 43 8

Amsoil Dominator 94 35 7

Motorex Cross Power 2T 110 60 NA

Motorex Power Synt 2T 108 50 9.1

Motul 710 2T 154 70 11

Maxima 927 218 155. 15

Motul 800 OR 2T 252 120 15

Note: Castrol (UK) Motul (France), Motorex (Switzerland) all comply with JASO FD and ISO L-EGD as well as API TC. Maxima and Amsoil, both USA companies did not go to expense of testing to meet other than API TC.

The Maxima 927 oil has been around a long time—since the 1970’s and was formulated for racing. Lower viscosity oils were developed to enable flow thru oil injector pumps rather than pre-mix. Maxima 927, like Motul 800 with higher viscosity and flashpoint was for pre-mix only. Maxima 927 is a blend of castor oil and synthetic. Castor oil can provide superior lubricity, but tends to create deposits when run at less than maximum output. Maxima claims to have solved this problem with blending. Pre-mix ratios are changed based on the type of use.

Motul 800 is designed for all out motorcycle racing, lots of full throttle, very high RPM operation. The others are designed for less severe use, less full throttle and lower RPM and are also suitable for chain saws, with intermittent full throttle. Air cooled motorcycle engines and chain saws operate under different conditions than an engine driving a propeller in an aircraft.

The ultralight aircraft is likely to see full throttle for for one to two minutes during takeoff and climb, and then would be at a lower RPM for cruise. Load for propeller equipped engines is more or less correlated to RPM. (Actually load increases at a faster rate than RPM, but for the range considered, assume it to be linear.)

There is no two stroke engine oil that is expressly designed for ultralights. (Blue Max is one exception that was marketed by the former importer of Hirth engines--but there were no specs provided for that oil--only marketing claims and the fact that it was not a synthetic oil.) In fact, Amsoil will not sell their oil for any "aircraft" application, and all oil manufacturers will be quick to assert that they do not recommend their oils for aircraft operations since they have never been tested for that application. (Amsoil and others probably just wanting to avoid legal suits but demands for oil in ultralights IS different from other applications.)

During that two minutes of climb (red), clearly Motul 800 with a high flash point and density would be a very good oil. But, during cruise (green) it might not vaporize and burn sufficiently to avoid smoke, oil in the muffler, and carbon deposits on the piston. And , during descent (yellow) it would not vaporize and burn sufficiently to avoid smoke, oil in muffler and carbon deposits.

Most likely the Motul 710 2T would be ideal for both cruise and descent. Feedback from users indicate that 710 is great for "normal" motorcycle operation, with 800 producing a lot of oil in the muffler, called "spooge".

The fuel/air/oil mixture flows into the crankcase. Being relatively "cool" the mixture directly cools and lubes the crankshaft and conn rod bearing which probably run at a temp below 150C. The mixture also impacts the lower cylinder, probably running at a slightly higher temp. In addition, the mixture also impacts the piston pin and bearing, cooling and lubing it. However, the piston is much hotter, probably running hotter than 150C. Here, a higher flash point can be attractive.

This all focuses on the oil's flash point and to a lesser extent, viscosity. Does the oil vaporize completely during this charging and transfer phase? How much, if any, is the lubrication of the piston pin and bearing affected if the temp is higher than the flashpoint? How much oil remains on cylinder walls?

Reviewing the specs for Castrol TTS, with a flashpoint of only 89C, and MZ201's manufacturer's recommendation, it would appear that a low flashpoint is not too much of an issue. This is confirmed by Aerolite 103 factory and US distributor for the MZ201 who claims Amsoil Dominator at 50:1 is being used with no problems, Motul 710 2T has a significantly higher flashpoint at 154C than Castrol TTS's 89C. And, Motorex’s Supersport racing oil has lower flash point and viscosity than Motul 710. (KTM exclusively uses Motorex, so they raced at “supersport” level with oil with less than 150C flash point, so perhaps higher flashpoint is not necessary. Motorex does recommend 40:1 for supersport racing.

Other than the mess of oil dripping from the muffler onto the ultralight's wings and tail, the another concern about using Motul 800 would be deposits---especially deposits that cause piston ring sticking and damage. Anecdotal evidence does not point toward carbon deposits with Motul 800, perhaps due to detergent efficiency. And anecdotal evidence with small high RPM motocross racing engines running Motorex (similar to Motul 710) shows more than sufficient lubrication after disassembly and inspection at 50 hours.

One possible "solution" would be to blend 710 and 800 together to raise the flash point and viscosity. Another would be to increase the ratio for 710 from 50:1 to 40:1 or even 30;1 while insuring a slightly rich above peak air fuel ratio, Another would be to use Motul 800 or Maxima 927 when ambient and cylinder head temps are high, living with the spooge generated during descent.

It is generally accepted that higher rpm requires a pre mix with more oil, e.g. 40:1 vs 50:1. It must be remembered that the MZ201 is running at half the rpm of racing motorcycles and less than 1/3 the rpm of racing karts.

It appears that whatever oil is chosen, due to the unique loads imposed on ultralight engines, optimum oil and ratio will result in some sponge at low loads encountered during descent. This provides an insight that best operation is to minimize idle and low rpm, using some throttle and higher rpm with lower descent rates during landing pattern. It also indicates that oil with more “solvent” which is used to reduce lower temp viscosity and flash point may be desirable in minimizing carbon deposits. The viscosity of the various oils at 200C “where it matters” are much more comparable than the 100C figures would indicate.

Motul recommendations:

Motul 710--Mixing ratio: from 2% to 4% (from 50:1 to 25:1) according to manufacturers' requirements.

Adjust according to your own use.

Motul 800 Mixing ratio: MOTO CROSS GRAND PRIX: 2% (50:1). In normal conditions decrease the percentage by 0.5%. (66:1) Tune according to your own use.

Engine size does affect the decision regarding the "best" oil and mixture. A one cylinder MZ engine will run at 50% higher RPM and likely to be run at maximum load for much longer to climb than a two cylinder MZ201. Another factor to consider is the effect of prop pitch on engine load. With an adjustable pitch prop, one can choose a setting that creates a higher climb rate, reducing the time at full throttle during take off and climb but requiring a higher RPM for cruise. If one planned on long cross country running, choosing a setting for low RPM at cruise would be ideal, overcoming the reduced climb rate by climbing in stages, limiting full throttle to 30-60 seconds at a time.

Also important to note is that changing oils and ratios probably will require an adjustment to the air/fuel ratio. Oil has as at least 10 times the viscosity of gasoline and higher viscosity oil will orequire larger (more rich) jetting. (The same vacuum pulling the thicker mixture will produce less flow.) Increasing the oil ratio from 50:1 to 40:1 will also reduce the combustible fuel thru the jetting, requiring more rich settings. In my opinion, an oil with a relatively lower viscosity, if sufficient to support oil film loads, will perform better than a relatively thick oil.

Based on the fact that Motul 710 2T is similar to Castrol TTS and Motorex, but with slightly higher flashpoint, and Motorex recommendation of 40:1 for racing, my best judgment indicates I will run Motul 710 2T at 40:1 (3.2 oz per gal = 2.5%) in my MZ201, being careful to control (limit) full throttle for extended periods of more than 60 seconds, and limiting off throttle idling on the ground and during descent. I will also run air fuel slightly on the rich side and will monitor CHT closely.

Absent testing, followed by disassembly and inspection, choosing the ideal oil and mixture is not possible. One can only choose a "conservative" strategy with the highest estimate of a good outcome, but having a "safety" factor. And, during operation, make close observations as to smoke, spooge, and CHT. One of the fundamental aspects of “unregulated” flight is personal responsibility—no FAA Reg’s certifying what products and procedures to use..you are responsible for determining what is best.

Additional Note: An often unrecognized characteristic of 2 stroke cycle engines, particularly those that are not fan cooled is the effect on air fuel mixture by crankcase temperatures. The crankcase temp of so called “air cooled” engines varies tremendously and hence the mixture can become dangerously lean when ambient temps are low. This is particularly critical during descent when power output is low and is made worse with fuels having low vapor pressure.

In addition, the volume to area ratio is also critical. A crankcase with a relatively large surface area relative to its volume is more likely to create lean air fuel ratios at low ambient temps. The MZ201 was designed originally as a two carburetor fan cooled engine. Reducing air flow with only one carburetor and eliminating the fan makes the engine particularly at risk for the dangers of lean air fuel rations—and potentially a complete engine shutdown when applying full throttle after a period of descent. This is the cause of my crash.